Technical datasheet

Print datasheet:

[Print advise: Scaling on portrait format => 54%, on landscape format => 84%]

Technical datasheet

|

Sumitube™ B20

Single Wall Polyolefin, 2:1

Operating temperature: -55 up to 135°C Surface: Matt

Marking: None |

|

|

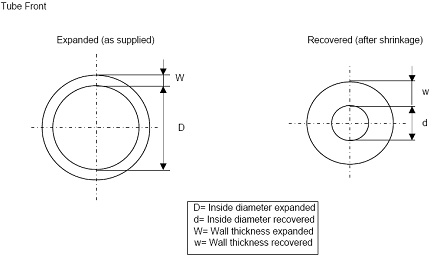

Dimensions

| TRADE SIZE | BEFORE SHRINKAGE | AFTER SHRINKAGE | DELIVERY UNITS * | ||

| [inch] |

Inner diameter (EID) min. [mm] |

Inner diameter (RID) max. [mm] |

Wall thickness (RWT) min.-max. [mm] |

Unit quantity [m] |

Box quantity [m] |

| 3/64 | 1,20 | 0,60 | 0,35-0,47 | 300 | 900 |

| 1/16 | 1,60 | 0,80 | 0,36-0,50 | 300 | 900 |

| 3/32 | 2,40 | 1,20 | 0,44-0,58 | 150 | 900 |

| 1/8 | 3,20 | 1,60 | 0,44-0,58 | 150 | 900 |

| 3/16 | 4,80 | 2,40 | 0,44-0,58 | 60 | 600 |

| 1/4 | 6,40 | 3,20 | 0,57-0,71 | 60 | 300 |

| 3/8 | 9,50 | 4,80 | 0,57-0,71 | 60 | 300 |

| 1/2 | 12,7 | 6,40 | 0,57-0,71 | 60 | 300 |

| 3/4 | 19,0 | 9,50 | 0,69-0,83 | 60 | 180 |

| 1 | 25,4 | 12,7 | 0,77-1,01 | 60 | 180 |

| 1-1/2 | 38,1 | 19,0 | 0,87-1,17 | 60 | 180 |

| 2 | 51,0 | 25,4 | 0,97-1,31 | 60 | 120 |

| * Spools in carton boxes -- Wall thickness (RWT) calculation method VG95343-2 --Special colours have no VG-approval. | |||||

Colours & Technical drawing

| STANDARD COLOURS | SPECIAL COLOURS | TECHNICAL DRAWING | |||||||||||||||||||||||||||

|

|

|

Technical properties

| PHYSICAL PROPERTIES | |||

| PROPERTY | TEST METHOD | REQUIREMENT | TYPICAL VALUE * |

| Longitudinal change | VG 95343-2 /-5 | 3 to -5% | -2% |

| Tensile strength | VG 95343-2 /-5 | Min. 10 MPa | 13.9 MPa |

| Elongation at break | VG 95343-2 /-5 | Min. 250% | 419% |

| Secant modulus | VG 95343-2 /-5 | 50 to 175 MPa | 138 MPa |

| Abrasion resistance (12.7mm/0.35kg) | VG 95343-2 /-5 | A: ≥1000 / B: ≥ 250 | Pass |

| THERMAL PROPERTIES | |||

| PROPERTY | TEST METHOD | REQUIREMENT | TYPICAL VALUE * |

| Operating temperature | VG 95343-2 /-5 | -55 up to 135°C | -55 up to 135°C |

| Min. shrink temperature | Shrink curve | Full recovery | 115°C |

| Shrinking starts at | Shrink curve | 75°C | |

| Thermal shock (200°C x 4h) | VG 95343-2 /-5 | No crack, flowing or dripping | Pass |

| - Tensile strength | Min. 10 MPa | 15.3 MPa | |

| - Elongation | Min. 200% | 472% | |

| Thermal ageing (150°C x 168h) | VG 95343-2 /-5 | No crack, flowing or dripping | Pass |

| - Tensile strength | Min. 10 MPa | 15.3 MPa | |

| - Elongation | Min. 150% | 432% | |

| Ability to bend under cold conditions (-55°C x 4h) | VG 95343-2 /-5 | No cracking | Pass |

| Compatibility with copper (150°C x 168h) | VG 95343-2 /-5 | Min. 200% elongation | Pass |

| Long term heat ageing (135°C x 3000h) | VG 95343-2 /-5 | Min. 100% elongation | Pass |

| CHEMICAL PROPERTIES | |||

| PROPERTY | TEST METHOD | REQUIREMENT | TYPICAL VALUE * |

| Combustion behaviour (self extinguishing in max. 15s) | VG 95343-2 /-5 | Procedure A | Pass |

| Water absorption | VG 95343-2 /-5 | Max. 0,5% | Pass |

| Resistance against chemicals (VG fluids incl. fuels) | VG 95343-2 /-5 | ||

| - Alteration in weight | Max. 10% | Pass | |

| - Tensile strength | Min. 8 MPa | Pass | |

| - Elongation | Min. 200% | Pass | |

| ELECTRICAL PROPERTIES | |||

| PROPERTY | TEST METHOD | REQUIREMENT | TYPICAL VALUE * |

| Voltage rating | UL224 | 600V | Pass |

| Dielectric strength | VG 95343-2 /-5 | ||

| - For dash-001 - 010: | Min. 200 kV/cm | 354 kV/cm | |

| - For dash-011 - 014: | Min. 100kV/cm | Pass | |

| Specific volume resistance | VG 95343-2 /-5 | Min. 1014 Ω·cm | Pass |

| * For reference purposes only |